Wood-plastic composites (WPCs) are composite materials made of wood fiber/wood flour and thermoplastic(s) such as PE, PP, PVC, or PLA.

The wood-plastic composite (WPC) product adopts a scientific and efficient production technology and enjoys an extensive technology extension. It is a project that utilizes the comprehensive development of waste resources and turns waste into treasure. The material can be sawed, cut, planed, nailed, and the performance of the product can be compared with hardwood products. The wood plastic product has stiffness and toughness, which can withstand static load and movement. The cost performance of plastic wood products is significantly better than other pure plastic or pure wood products.

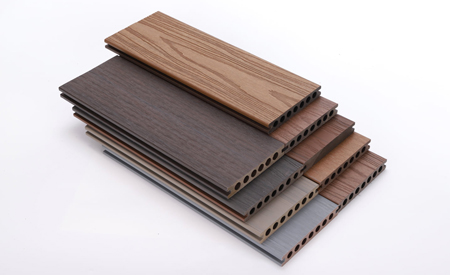

Wood-plastic composites are still new materials relative to the long history of natural lumber as a building material. The most widespread use of WPCs in North America is in outdoor deck floors, but it is also used for railings, fences, landscaping timbers, cladding and siding, park benches, molding and trim, window and door frames, and indoor furniture. Manufacturers claim that wood-plastic composite is more environmentally friendly and requires less maintenance than the alternatives of solid wood treated with preservatives or solid wood of rot-resistant species. These materials can be molded with or without simulated wood grain details.

Sundi has the whole range of WPC products including decking, railing, pergola, etc., both co-extruded and general type.

WPC means Wood Plastic Composite. PVC means polymerization of vinyl chloride.

PVC floor is afraid of cigarette burns, sharp scratches; WPC floor is fire resistance which could be fire prevention level reached B1.

PVC floor is not natural material, it was made of the floor that uses polyvinyl chloride material to produce. Specifically, PVC and its copolymer resin as the main raw material, add accessories, on a continuous sheet substrate, by coating process or by calendaring, extrusion or extrusion process from production.

Wood-plastic composite WPC floor is a new type of composite material with high performance and high added value, which is made of wood and recycled plastics using special surface treatment.

The PVC floor has good thermal conductivity, uniform heat dissipation and small thermal expansion coefficient, and is relatively stable. WPC floor thermal bad conductor, if the external environment temperature changes greatly, then the surface and the internal heating is not uniform, it is easy to produce expansion and shrinkage deformation, long-term effect will make the life of wood-plastic floor shorten.

WPCs are often considered a sustainable material because they can be made using recycled plastics and the waste products of the wood industry. They are the ideal green sustainable solution that makes use of organic material with virgin, recycled or renewable plastics, normally High-Density Polyethylene (HDPE).

WPC Decking is produced without pollutants during processing, do not pollute the environment. In use, WPC decking has the secondary processing properties similar to wood, which can be cut, glued and fixed with nails or bolts. Because WPC Decking with high performance, weaken the base material in residue molecular activity, to make the residual material inside the plate isolation with the outside world and reduce the volatilization of harmful substances, also do not need to use the paint on the late maintenance, just clean it with water and keep it like new for a long time. It is engineered to look like real wood. Most composite decks are recyclable and it is the best to choose due to its durability.